Units of measurement, symbols, significant digits and rounding off

1.1 Units of measurement and symbols

1.2 Significant digits

1.3 Rounding off

1.4 Bias, accuracy and precision

Individual Trees and Logs

2.1 Bole characteristics

2.1.1 Diameter

2.1.2 Height

2.1.3 Bark thickness

2.1.4 Volume

2.1.5 Stem form and taper

2.2 Log characteristics

2.2.1 Diameter

2.2.2 Length

2.2.3 Volume

2.2.4 Weight

2.2.5 Allowance for defect

2.3 Crown characteristics

2.3.1 Width

2.3.2 Depth

2.3.3 Surface area

2.3.4 Volume

2.3.5 Biomass

2.4 Stem analysis

Groups of Trees (Stands)

3.1 Number of trees

3.2 Diameter

3.3 Basal area

3.3.1 Fixed-area plots

3.3.2 Angle count sampling

3.3.3 Advantages and disadvantages of angle count sampling

3.4 Height

3.4.1 Mean height

3.4.2 Predominant height, top height, dominant height

3.4.3 Stand height curve

3.5 Volume

3.6 Crown closure

3.7 Crown biomass

3.8 Growth and increment

References

Appendix 1: Checklist of equipment and materials

[RWG#2] [Copyright] [Title Page] [Next Page] [Last Page]

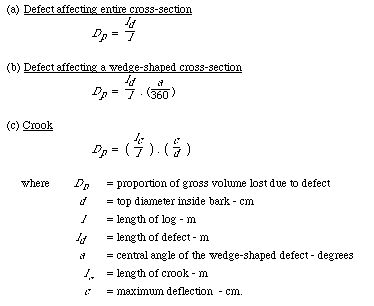

2.2.5 ALLOWANCE FOR DEFECT

Traditionally, log defect refers to those imperfections which result in the complete loss of some of the volume of a log when it is sawn. It poses a problem when log quantity is estimated. Overcoming it requires that log grading rules be applied which specify the allowance (scale deduction) to be made for each type of defect, viz. rots, insect flight passages, ring shakes, checks, splits and crooks. Note that features such as size and frequency of sound knots, spiral grain, sap-stains, resin pockets, bark inclusions, etc. are not considered to be defects because they do not affect the quantity of the sawn produce - although they degrade its quality. Allowance for the impact of these 'degraders' on the value of the sawn timber is made in the mill during the routine grading of the sawn produce.

One of the most serious defects in sawlogs of Australian tree species is pipe which is the rotted, central longitudinal core found in many mature eucalypts and rain forest tree species. Allowance for pipe is usually computed assuming that the cross section of the pipe is a square of side equal to the pipe diameter. Commonly, allowance is made by measuring the diameter of the defect at each end of the log (to the nearest whole centimetre above) and averaging the two. Volume of defect is then this measurement squared times the log length.

Making deductions for log defect requires that one determine the type and extent of the defect and then compute the loss. Grosenbaugh (1952) provided a consistent set of rules for doing this, some of which have universal application: